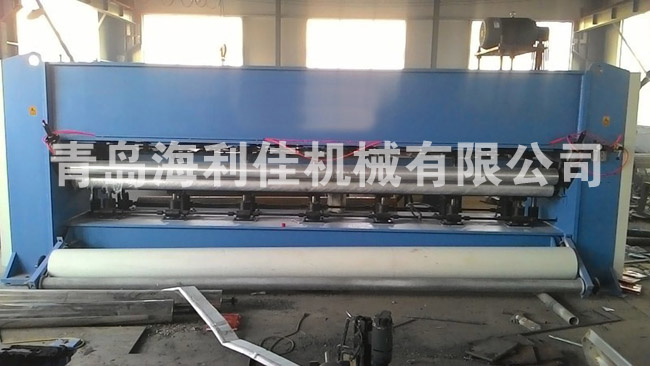

Glass fiber production line

Detailed Description

The device can be non-stop unwind and rewind roll change, reduce waste, reduce costs, unwinding and rewinding adopt automatic tension control system, control of high precision rolling effect, winding diameter up to 1.5 meters and lengths up to 1700 m coated head glue evenly, do not scratch cloth

Device structures

Machine including Elevating unwinding unit, straight blade coating head, hot hair several parts of the oven, cooled traction unit, flip duplex winding unit, rack, hot air circulation and ventilation system, electrical control system

The main technical parameters

1. Effective coating width: 1300mm

2. The roller surface width: 1450mm

3. The maximum mechanical speed: 30m / min

4. Production speed: 1-30m / min

5. Maximum unwinding diameter: 1400mm

6. Maximum rewinding diameter: 1200mm

7. oven forms: hot air

8. Heat source: natural gas / electrical / thermal oil / coal

9. Electrical power: about 55KW

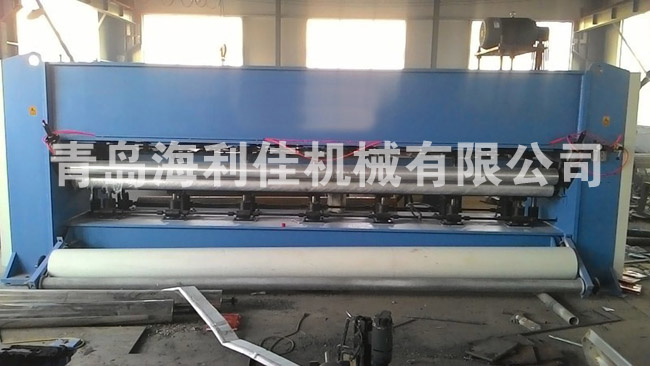

Device structures

Machine including Elevating unwinding unit, straight blade coating head, hot hair several parts of the oven, cooled traction unit, flip duplex winding unit, rack, hot air circulation and ventilation system, electrical control system

The main technical parameters

1. Effective coating width: 1300mm

2. The roller surface width: 1450mm

3. The maximum mechanical speed: 30m / min

4. Production speed: 1-30m / min

5. Maximum unwinding diameter: 1400mm

6. Maximum rewinding diameter: 1200mm

7. oven forms: hot air

8. Heat source: natural gas / electrical / thermal oil / coal

9. Electrical power: about 55KW

【Print this page】 【Close】